Warehouse racking is central for the part in effective storage management, permitting firms to improve space, increase accessibility, and greatly enhance productiveness inside their facilities. With different racking programs obtainable, warehouses can proficiently Arrange and retail outlet products determined by their distinct demands, from modest conditions to bulk items. Selecting the proper racking process not only maximizes storage capability as well as guarantees employee safety and clean functions.

Forms of Warehouse Racking

A number of types of racking systems are commonly utilized in warehouses, each with special pros tailored to various storage specifications:

Selective Pallet Racking: This can be the most regular racking system, supplying direct access to each pallet. It’s really adaptable, rendering it ideal for warehouses which has a large turnover of various goods. Selective racking maximizes accessibility, While it won't be as Place-successful as other techniques.

Travel-In/Generate-Through Racking: Created for large-density storage, travel-in racking makes it possible for forklifts to have in the racking system to carry and retrieve pallets. It’s great for storing massive volumes of similar elements of a last-in, initially-out (LIFO) system. Generate-via racking, Then again, follows a first-in, initial-out (FIFO) technique and is particularly great for inventory rotation.

Cantilever Racking: Most effective suited for storing lengthy, cumbersome such issues as pipes, lumber, and metal rods, cantilever racks give open up fronts that simplify loading and unloading. They in many cases are located in building and production facilities where by prolonged elements demand versatile storage.

Drive Back Racking: This technique makes use of a series of nested carts that roll alongside rails, permitting pallets to have saved two to six deep. It’s a reliable, large-density Alternative for things that don’t have to have immediate retrieval, working about a LIFO technique.

Mezzanine Racking: By introducing a next as well as third level to some warehouse, mezzanine racking proficiently doubles or triples out there ground House with out expanding the building by itself. This system is perfect for maximizing vertical Room.

Benefits of Helpful Warehouse Racking

An successful racking technique substantially boosts warehouse operations by optimizing House utilization, increasing accessibility, and reducing retrieval periods. This sales opportunities to better inventory administration, as things are available and organized, which minimizes labor expenditures and raises productiveness.

Racking units also advertise basic safety by supplying structured and stable storage. Adequately designed racks sluggish up the chance of incidents, making sure a secure and protected atmosphere for the two employees and inventory. In addition, effectively-taken care of racking methods decrease damage to saved objects, improving inventory lifespan.

Deciding on the Suitable Racking Process

Picking get more info out the correct racking process is dependent upon aspects like available Place, inventory form, turnover charge, and budget. An intensive evaluation of storage demands and operational flow can be valuable for deciding on a racking procedure that supports streamlined workflows and maximizes warehouse efficiency. Appropriately executed, warehouse racking is definitely an financial commitment that requires care of in Room discounts, protection, and extensive-term efficiency.

Tony Danza Then & Now!

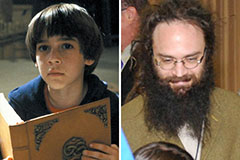

Tony Danza Then & Now! Barret Oliver Then & Now!

Barret Oliver Then & Now! Val Kilmer Then & Now!

Val Kilmer Then & Now! Joshua Jackson Then & Now!

Joshua Jackson Then & Now! Tiffany Trump Then & Now!

Tiffany Trump Then & Now!